Successful start-up in Aschaffenburg

DS Smith, the leading manufacturer of recyclable packaging for consumer goods, produces approximately 420,000 t/y of corrugated board base paper at its headquarters in Aschaffenburg .

As part of the expansion of the stock preparation plant, the company included plans for the replacement of the existing rejects dewatering system. The reject consists of fibre residues and cleaner reject. In addition to the profitability of the project, the most important criteria for the choice of supplier were a very high final dryness and optimum clarified water quality. Before placing the order, DS Smith had been able to assess Bellmer Kufferath’s abilities through a number of pilot plant trials carried out on site in Aschaffenburg. Dryness values of > 60 % were reached in all possible conditions.

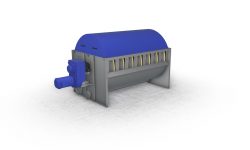

The new fine rejects dewatering system delivered at the end of 2016 was put in operation quickly and successfully in March 2017. It includes a flocculation reactor, an AKSE S 175/07 disc thickener and an AKUPRESS BX 625 LL-H screw press.

Assuming the stock consistency of the reject to be approximately 2-3 %, the dewatering unit has been designed for a capacity of 50 t/d BD (up to a maximum of 60 t/d BD), making it possible to achieve a dry content of more than 60 %.

Assistant Plant Manager Mr. Olsson, who was also in charge of project management, has reported that the system operates reliably and to their complete satisfaction.

Get more information

Get further information about the Bellmer AKSE here.

Or just contact us:akse@bellmer.com

Get more information

You can get further information about the Bellmer AKUPRESS here.

Or just contact us: screwpress@bellmer.com