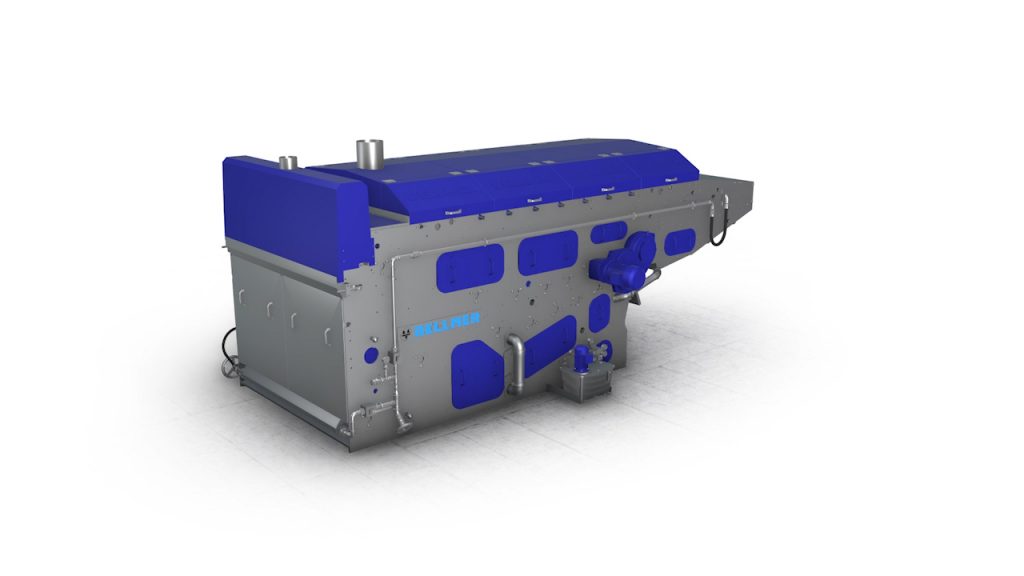

Belt Press – WinklePress

With over 50 years of experience in the field of belt presses, Bellmer consistently leads the mechanical sludge dewatering market. The WinklePress offers the lowest operational costs and best dry contents results. The Bellmer belt press is perfectly adapted to today’s needs and to changes in sludge composition. The optimized roller configuration achieves higher dry solids content. With the help of the single roller gradations, the pressing time within the machine is considerably extended. This is most beneficial when dealing with the sludge of low press stability and a high organic content. Minimum operating costs and highest efficiency-class motors guarantee lowest possible energy consumption. Cleaning and handling operations are easy thanks to large inspection opening.

Learn all about the easy handling of the machine and assess the thickening process yourself.

Test our mobile unit!

Advantages:

- Highest dewatering results

- Low operating costs

- Low energy costs

- Minimal spray water consumption

- Clean and closed operation

- Easy cleaning and handling

Unique process technology

To achieve best operational results with a belt filter press, you need a slowly increasing pressure on the sludge. Because of this, the WinklePress offers an optimal dewatering concept with six different dewatering stages. The unique process technology is particularly helpful for sludge with low press stability and high organic content. We optimized the roller configuration to reach higher final dry solids contents. Here, a long pressing time within the machine is key.

Custom tailored

Bellmer offers customized WinklePress designs, adapted to your specific sludge characteristics and particular applications. One solution to obtain optimal flexibility, more hydraulic load and a stable performance for unpredictable conditions, is the Bellmer Cascade: A combination of thickening and dewatering in one process step.

Please contact us for further information: cascade@bellmer.com

Cost efficient

The WinklePress allows significant savings of resources, which results in considerable cost reductions. In detail, the belt press allows polymer, energy and maintenance savings. These possible savings per year quickly sum up. Do you want to estimate your possible savings? We will be delighted to work out your personal calculation and annual savings.

Test us on your site!

Test us now with our mobile unit! Afterwards, you decide which solution is the most efficient and economical for you. With the help of real test results, we determine optimal plant configuration as well as sludge volume tests.

Just contact us: winklepress@bellmer.com