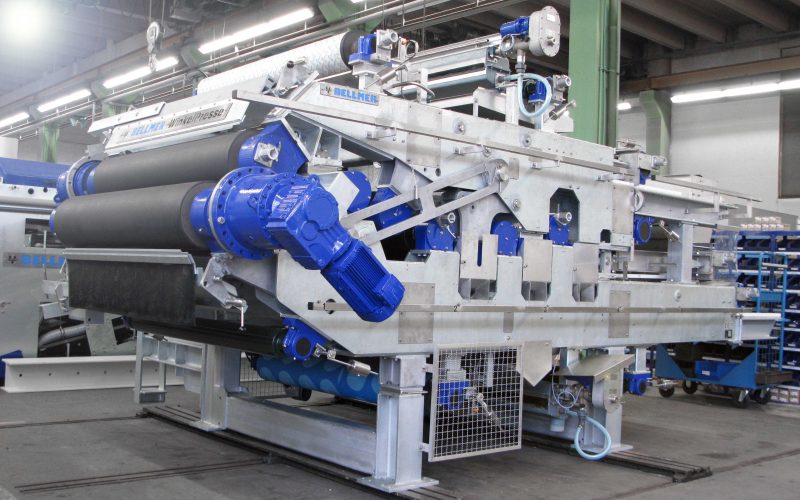

High pressure – WinklePress H

For a high-pressure dewatering process of residual materials, principally from paper sludge, the WinklePress H is the optimal choice. With the WinklePress H dry solids contents of more than ~60% can be reached. Consequently, there is an extreme reduction of disposal cost of the dry sludge. Additionally, the paper sludge can be used as an optimal energy source for incineration in power plants without sustaining fire.

Advantages:

- High DS-contents

- Low maintenance requirement

- Stable and reliable process

- High flexibility (inlet solids content / throughput)

- Low flocculent consumption

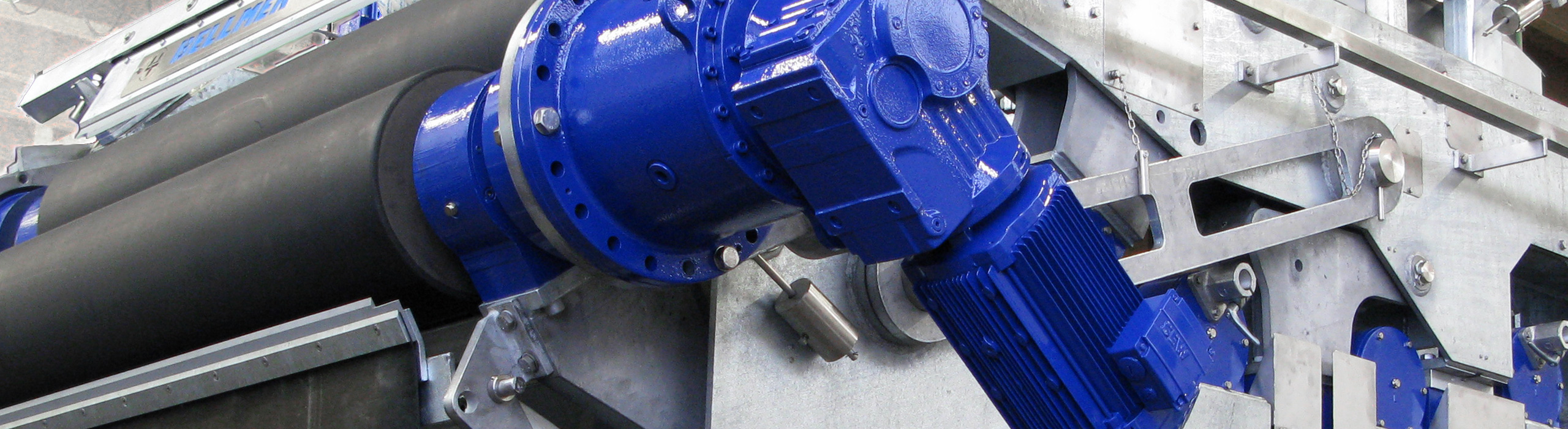

High-Pressure Forces

Due to special sludge characteristics with a high proportion of minerals or fibers, high-pressure forces are required to reach high dry solids after the thickening and dewatering process. To reach these high-pressure forces on the sludge several steps are needed:

First, Bellmer developed a particular distribution system, which ensures a smooth spreading procedure of the sludge over the entire belt width. Second, in the pre-dewatering zone, the pressure on the sludge is slowly increased until the high-pressure section where the sludge endures high-pressure forces. The press section of the WPH is particularly designed and optimally adapted to reach best dry end test results. Especially the graduation of the roller diameters is of importance.

Get more information

You need high dry solids results and want to test the values for a long-term decision? Test us now with our mobile unit. You will learn everything about your possible savings and possible end results. Learn all about the easy handling of the machine and asses the high-pressure process yourself.

Just contact us: winklepress-wph@bellmer.com