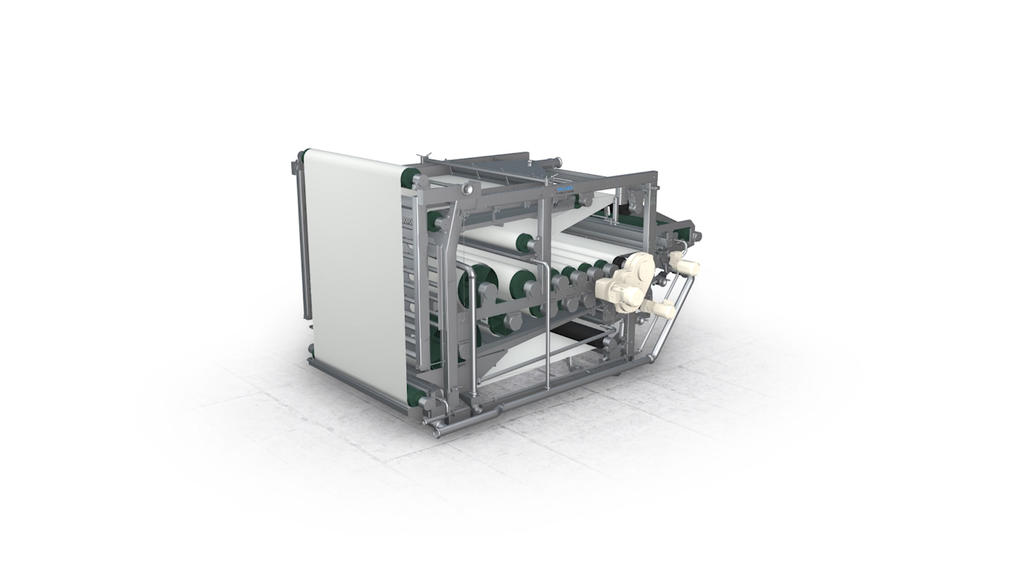

Fruit Press – WinklePress WPX

The special design of the WinklePress WPX allows our customers to achieve high yields in their fruit extraction and food processing process. Generally, the fruit press WinklePress offers up to six juice extraction stages. With this increasing pressure we achieve higher results compared to other belt filter presses on the market. Additionally, the WinklePress offers a good accessibility for the user and an easy cleaning procedure. For instance, due coated rollers with a smooth surface called rilsan, cleaning is much easier compared to stainless steel rollers. Furthermore, the frame of the machine is made of stainless steel for an optimal quality and a high hygienic standard.

Advantages:

- Juice extraction process in six stages

- Continuous operation

- Short pressing periods

- Low turbidity and operation costs

- Few maintenance required

Six dewatering steps

Pre-extraction:

Through an adjustable mash feeding nozzle the mash is fed equally across a horizontal belt so that a large part of the juice runs off as a result of gravity.

Wedge area:

In the unique wedge area the two circulating belts form a vertical, wedge-shaped chute with a variable opening that enables a gentle extraction. The extraction is effected by slowly increasing pressure, which arises from the height of the chute and the setting angle. Thanks to the vertical wedge zone extraction to both sides is possible. The wedge sealing prevents the spilling over of the mash.

Low pressure zone:

The big diameter of the first perforated roller affects a gentle pressure build-up. Thickening of the mash is the optimal basis for an extraction in the following steps.

Press zone:

In the s-shaped high-pressure press rollers especially designed for the WPX further extract the mash between the belts. By the diminution of the diameter of the rollers pressure is increased. The configuration of the rollers is optimised and enables highest yields and final dry solids content in the pomace.

High pressure zone (optional):

It is possible to achieve still higher yields and final dry solids content in the press zone with an additional high pressure zone, that exists of 4 press rollers and the pressnip described as follows.

Pressnip (optional):

The pressnip, well known in the paper industry, causes a marked improvement in fruit processing, too. This in addition to the adjustable nip pressure still increases yields and final dry solids content.

Get more information

Our specialists are looking forward to take on also your new fruit juice project.

Just contact us: fruitjuice@bellmer.com