Bellmer Vaahto has made a complete pulper delivery to VPK Paper Oudegem in Belgium.

The under-winder pulper of PM 6 has the capacity to handle side trims and waste paper up to 250 t/d. The mill manufactures testliner and fluting grades in basis weights 100 – 210 g/m2. The trim width of PM6 is 4.86 m.

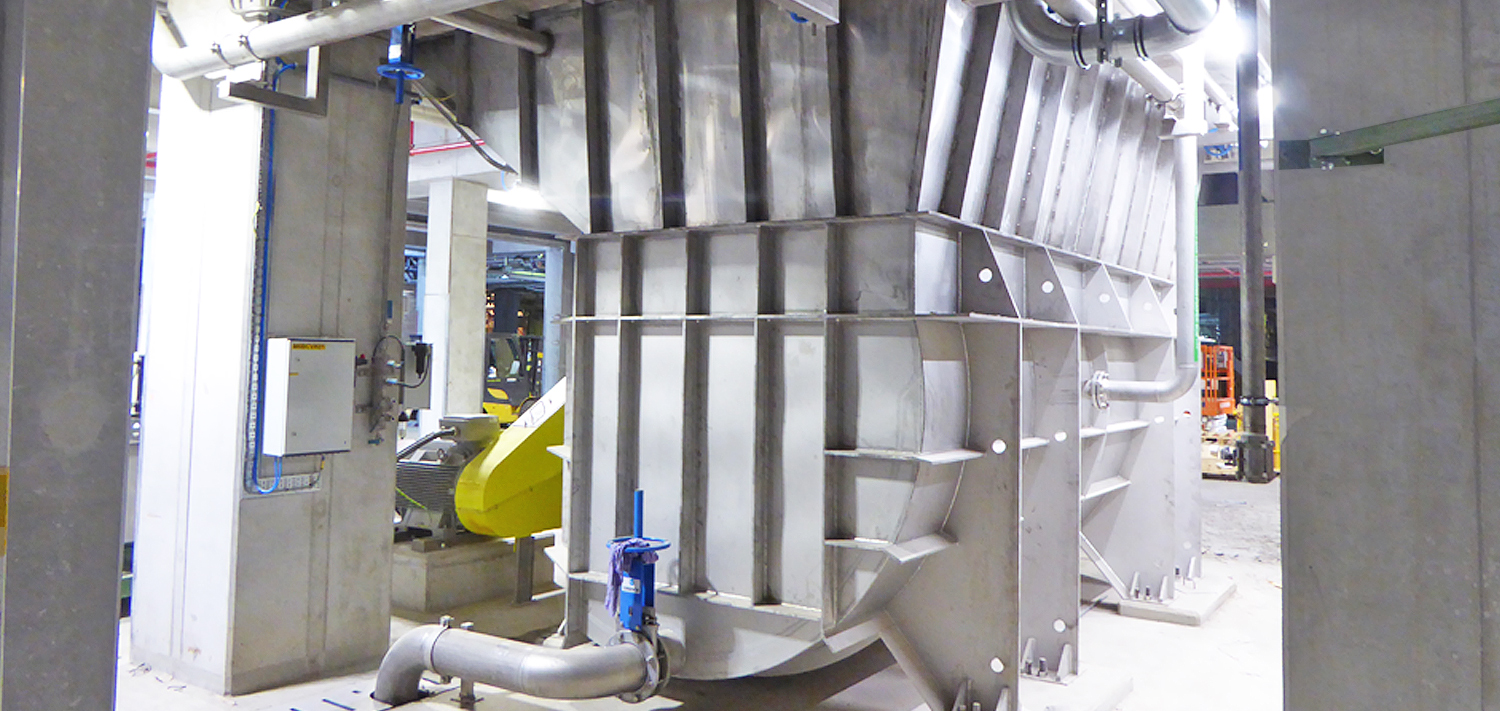

The TurboPulper VDS 33 is equipped with one effective rotor unit. The vat is specially designed to ensure good mixing of the stock without splashing, while the chutes and showers provide trouble-free feeding of trims and waste paper into the pulper. The dwell time of the stock is approximately four minutes.

All equipment was made in Bellmer Vaahto´s workshop in Hollola Finland. Erection supervision was an essential part of the delivery.

VPK Paper started operation in 1935 and is today one of the leading papermills in the region. It converts 500,000 t/y of waste paper and recycled board to produce the same quantity of packaging boards. The mill also produces solid board and coreboard.

Get more information

You can get further information about the Bellmer TurboPulper here.

Or just contact us: pulper@bellmer.com