New automation of InfraLeuna WinklePress

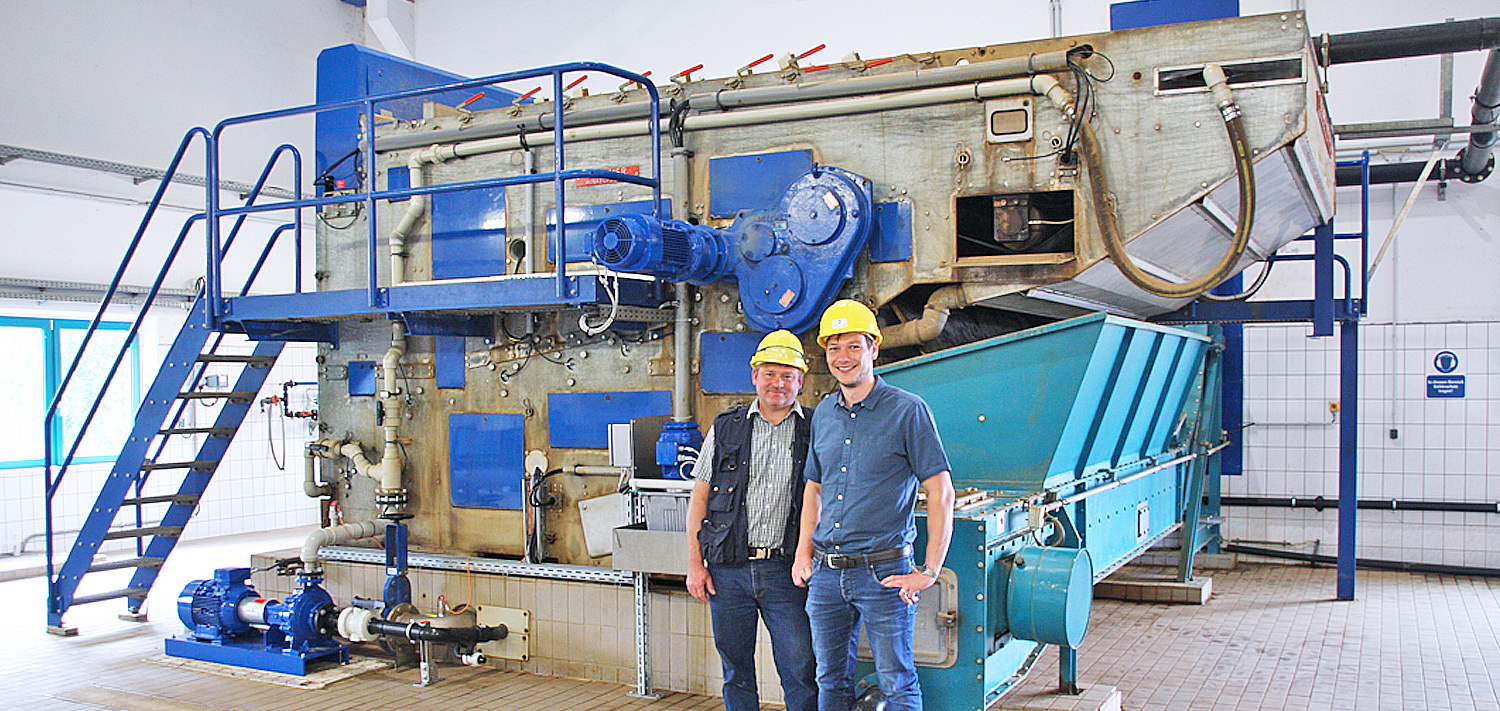

InfraLeuna GmbH owns and operates on-site facilities for the supply of water at the chemical site Leuna. Fresh water for the Leuna site’s process water supply is produced in the Daspig waterworks from the surface water of the River Saale. A WinklePress™ WP-4 has reliably dewatered the incidental sludge for several years.

However, as part of a centralization process, it was decided to introduce an increased degree of automation in the systems which had previously had independent control centers. Following intensive technical discussions with Bellmer and a professional engineering firm, the order was given to Bellmer to automate the plant as far as possible.

Bellmer’s SystemControl automation solution now controls the machine. With the help of sensors at the inlet and within the machine, the wire speed, throughput, solids load and the polymer dosage are controlled for an optimum dewatering result. Other internal machine functions, such as spray tube cleaning, were completely automated. The EMSR technology for the entire plant was renewed, including a connection to the central control room.

The plant was not only modernized with state-of-the-art solutions, but the primary objective of being able to operate and monitor the plant virtually without supervision by the central control room has also been achieved. The work was carried out within a few days, and the plant put back into operation again. With the project complete, the Bellmer WinklePress™ continues to dewater sludge reliably and with the best possible dewatering results.

Get more information

You can get further information about the Bellmer Automation Systems here.

Or just contact us: automation@bellmer.com