The number of TurboPress shoe presses exceeds 138 as of the end of 2021. The majority of the shoe press customers are located in the 25 countries of the world with the highest industrial production, and the TurboPress shoe presses run in machines that could hardly be more different. Speeds from 150 to 1800 m/min, working widths from 2,200 to 7,500 mm and line loads from 200 to 1600 N/mm are served.

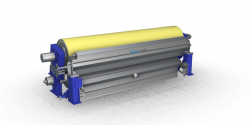

The secret of success, apart from the technical and technological know-how and the well-known Bellmer service and support from quotation to commissioning, lies in the diversity of TurboPress shoe press designs offered. Depending on customer objectives, technological requirements of the paper grade and the installation situation (e.g., space conditions and crane capacities in case of rebuilds), we select the appropriate TurboPress concept for the respective project.

Ultimately, the design is determined by the production speed, the required line load, the existing PM, the available space in the building, and the crane. Thus, the discussion about the customer’s requirements and goals for the rebuild is the starting point for the customized solution of the press concept.

Bellmer shoe presses undergo a unique quality control process. Only at Bellmer are all TurboPresses put through their paces on our test bench after pre-assembly and before delivery. Did you know, that according to the belt manufacturers, the TurboPress has the longest belt lifetime of all shoe presses on the market?

We would be happy to create a tailor-made concept for you! Learn more about the technical details of the TurboPress to increase dry content, increase production or improve physical paper properties.

Get more information

You can get more information about our shoe press TurboPress here.

Or just contact us: shoepress@bellmer.com